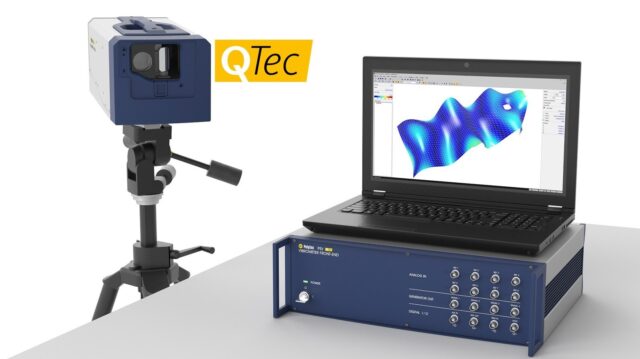

Polytec IVS-500 industrial vibration sensor delivers precise acoustic quality inspection and structure-borne noise analysis for dependable pass-fail evaluations. Operating with laser precision, this non-contact sensor ensures accurate, wear-free measurement across nearly all surfaces, even under tough industrial conditions. By minimizing false rejections in production and assembly, it helps optimize both costs and yield.

Main Advantages

– Consistent and repeatable pass-fail results for production testing

– Reliable non-contact quality checks using advanced laser technology

– Adjustable working distances up to 3 m with auto focus

– Broad application capability covering frequencies up to 100 kHz

– Durable and maintenance-free sensor design

– Easy in-line or at-line setup and integration

– Output available as velocity, displacement, or acceleration data

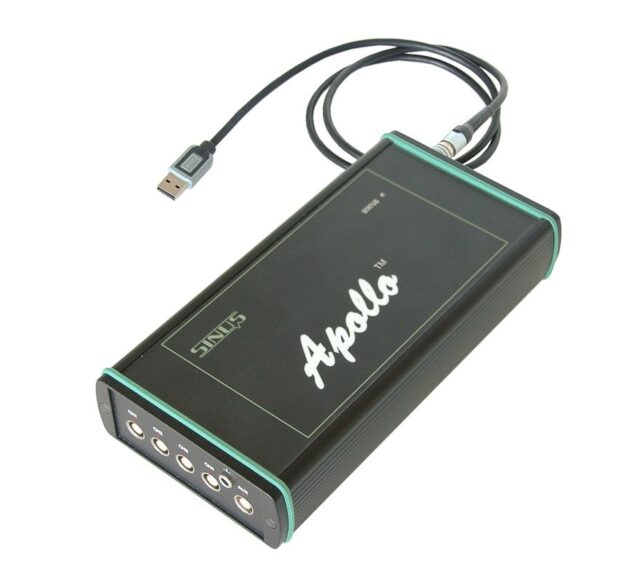

– Supports both analog and optional digital signal formats

Cost-Effective and Flexible Quality Control

The IVS-500’s rugged construction and straightforward installation enable smooth integration into automated production test systems. When paired with Polytec’s SonicTC QuickCheck software, it offers a complete solution for accurate and reliable pass-fail evaluation. The compact, all-in-one unit incorporates built-in decoding electronics for simplified operation.